ANPADEH

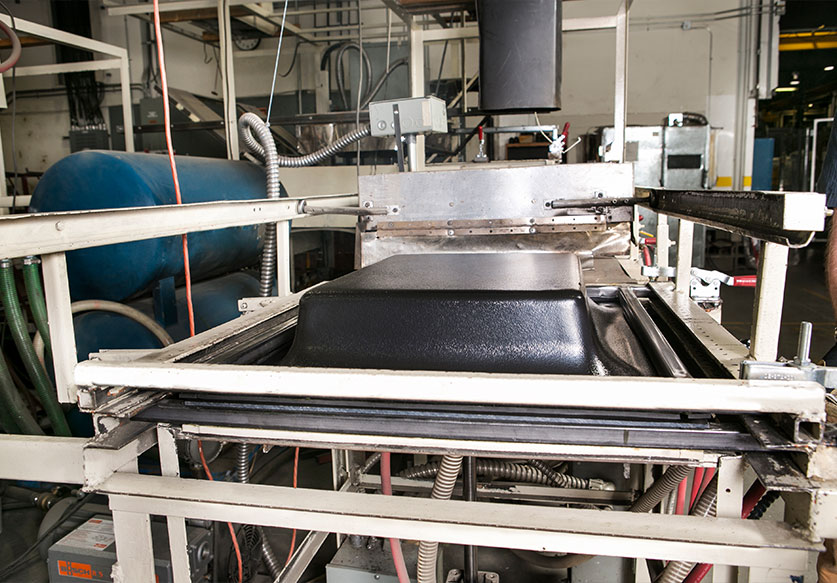

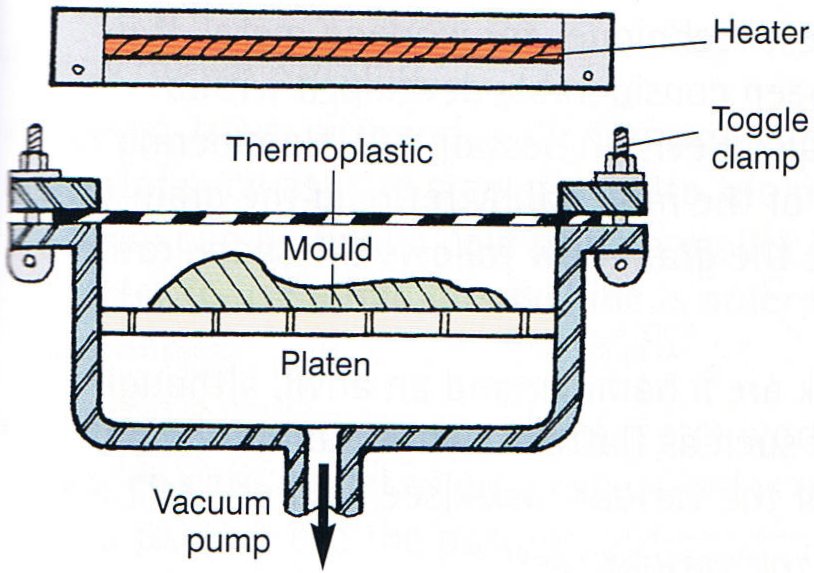

Vacuum Forming Vacuum forming is the process of evacuating air from the sealed space between the hot sheet and the mold, thus allowing atmospheric pressure (14.7 p.s.i.) to force the sheet to conform with the contour of the mold. The most basic of the thermoforming processes, vacuum forming can be ideal when you need durable plastic parts

Plastic Vacuum Forming Thermoforming Blow Molding Injection Molding Universal Plastics

CAPABILITIES: Vacuum forming is a one-sided process. The finished part will have shape and detail on one side. The advantages to vacuum forming are less expensive tooling, faster turn-around and easier, less expensive updates and modifications compared to injection molding. Thermoformed (or vacuum formed, as it is also known) plastic is THE.

What are the benefits of vacuum forming? Move to a new phase

Thermoformed Products. Drader Manufacturing Thermoforming & Vacuum Forming is an easy, cost-effective plastic manufacturing alternative to protect, store & transport your products with confidence. Our complete mold making facility is highly adaptable to any application and low- or high-volume production. Customers from an array of industries.

10 Products Made By Vacuum Thermoforming Global Thermoforming

Vacuum forming is a way to manufacture plastics in which large sheets of thermoplastic are heated until malleable but still solid, then fitted over a custom mold, typically made from aluminum. There are small vents in the mold, and once the plastic is stretched over the mold properly, a vacuum is turned on.

Thermoformed & Vacuum Formed Products Drader Manufacturing Industries, Ltd.

Vacuum thermoforming is a plastic thermoforming manufacturing technique within the broader term of the plastic thermoforming process.In vacuum forming a 2 dimensional thermoplastic sheet material is heated to a forming optimal temperature and then positioned over a custom mold or tool.Then, the air is evacuated between the heated sheet and mold creating a vacuum that pulls the material onto.

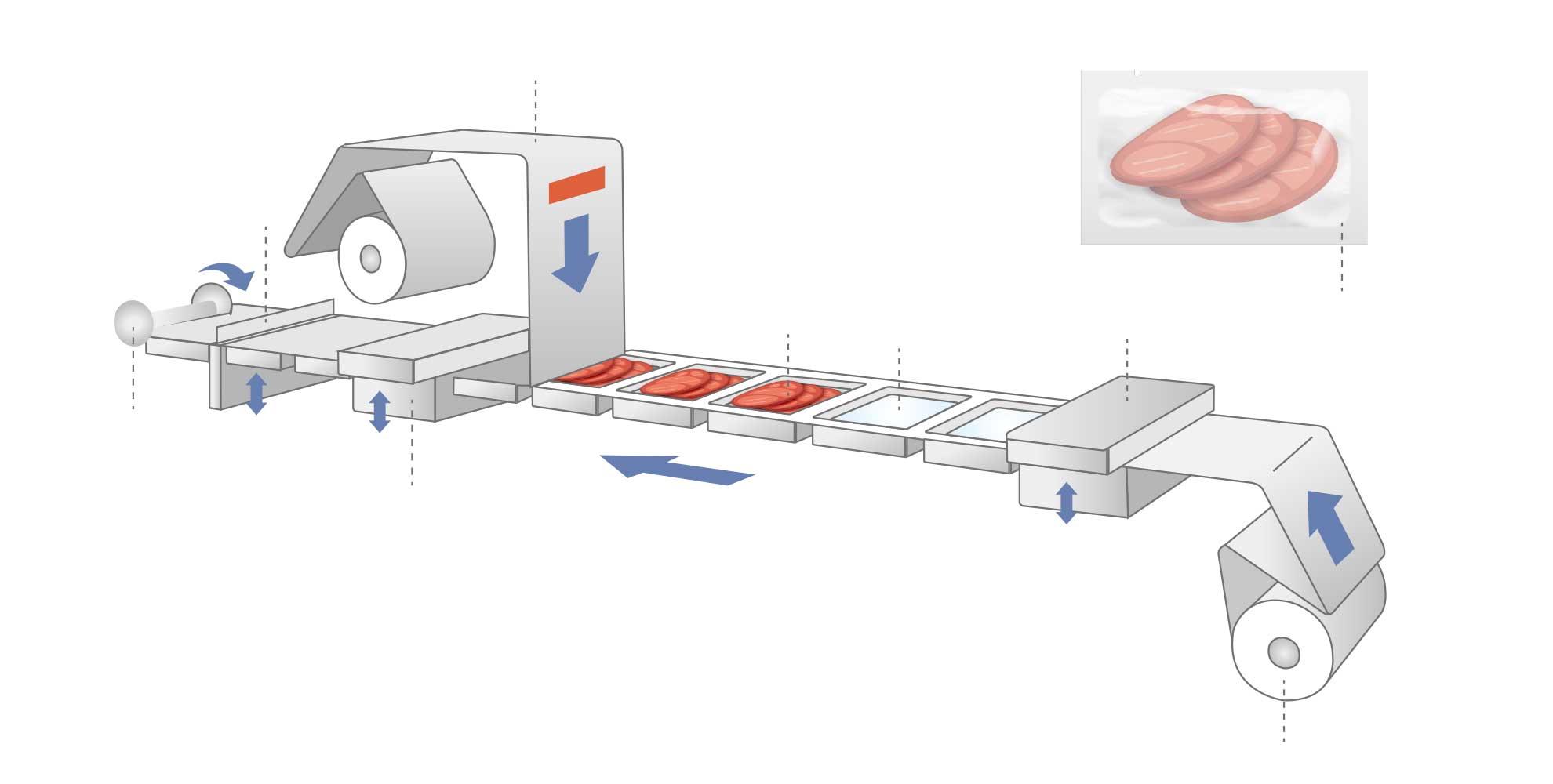

InLine Thermoforming / Vacuum Forming KD Packaging

Thermoforming is a highly economical process for the million-fold manufacture of products such as the previously mentioned beaker lids as well as blister packs and trays. In all cases, the first step is to heat up a two-dimensional plastic film or sheet and then, under a vacuum or with compressed air, press it against the contours of a mould.

ANPADEH

Germany: Browse through 52 potential providers in the thermoforming industry on Europages, a worldwide B2B sourcing platform.

шоссейнокольцевые мотоциклы СССР Форум onliner.by

Thermoforming is a plastic manufacturing process that uses pressure or the force of a vacuum to stretch thermoplastic material over a mold to create a three-dimensional shape, part, configuration, or other form of plastic product. Cups, containers, lids, trays, and clamshells are formed by thermoforming using thin sheets of thermoplastic, while.

Thermoforming Vacuum Packaging Machine

Thermoforming is a versatile manufacturing process that uses heat and pressure to shape plastic into parts. Sheets of plastic are heated so they can be manipulated into whatever shape is needed. Once the sheet reaches the proper temperature, it is formed to create the desired product.

What is Thermoforming? Plastic Thermoforming Explained Productive Plastics

Germany: Browse through 6 potential providers in the vacuum thermoforming industry on Europages, a worldwide B2B sourcing platform. The B2B Sourcing Platform Close

10 Products Made By Vacuum Thermoforming Global Thermoforming

Home Store Vacuum Formers & Thermoformers Vacuum Formers & Thermoformers Vacuum forming is a process in which a sheet of plastic is heated until it is pliable and then stretched over a mold. A vacuum is applied to the mold, which pulls the plastic tightly over the mold, creating a precise shape.

10 Products Made By Vacuum Thermoforming Global Thermoforming

Watch on Vacuum forming is used for a wide range of manufacturing applications, ranging from small custom parts produced on desktop devices to large parts manufactured on automated industrial machinery. What are the Differences Between Vacuum Forming, Thermoforming, and Pressure Forming?

About Thermoforming Vacuum Packaging Thermoforming Vacuum Packaging Machine Manufacturer

Germany: Browse through 16 potential providers in the vacuum forming industry on Europages, a worldwide B2B sourcing platform.

Thermoforming Products Plastics Unlimited

The Thermoforming Process. Thermoforming is a process where thermoplastic sheets are heated to a pliable temperature, formed to a specific shape using a mold, and trimmed to create a finished product. Vacuum Forming takes it one step further. When the part is formed to the mold, vacuum pressure is added to assist with the molding of the part.

Thermoforming Vacuum Packaging Machines LENIS MACHINES INC.

Thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific shapes. The shaped plastic then gets cooled down and trimmed to result in the finished part. The process is executed using a thermoforming machine to heat and stretch the pliable thermoplastic sheet over the mold.

Thermoplastic vacuum forming plastic with Interform Manufacturing

Versatile Thermoplastics Real thermoplastics are strong, durable and inexpensive compared to 3D printed materials. RapidMade offers an extensive range of thermoforming plastics, including PETG, HIPS, ABS, PC, Acrylic and many more, in thicknesses ranging from 0.020″ to 0.250″ (0.5 mm to .6.5 mm).